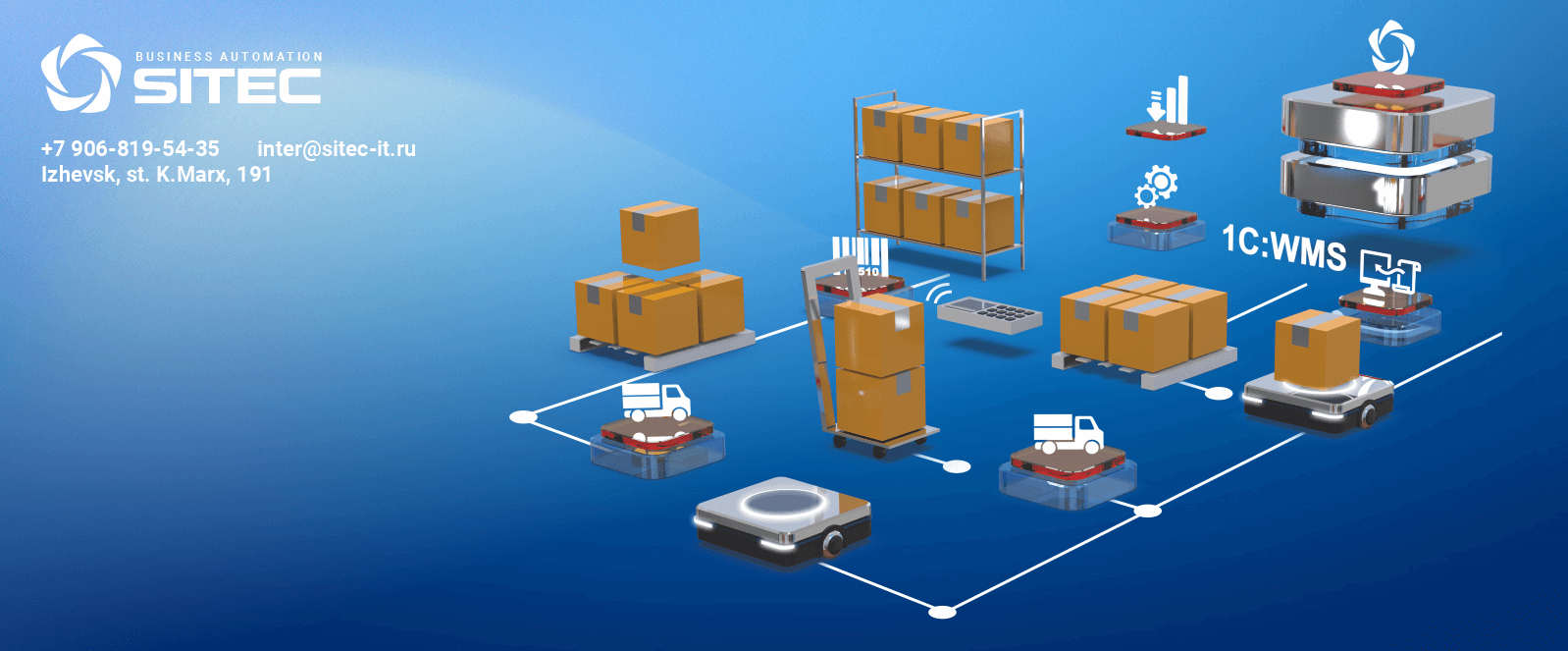

"1C:WMS" is not just an IT solution, but also your reliable partner in optimizing of all warehouse processes. It provides centralized management of all warehouse processes: from goods receiving, movement, inventory, picking, to shipping. Intelligent planning and routing of goods movement increases the efficiency of using warehouse space and reduces the time for generate orders.

"1C:WMS" provides:

"1C:WMS" provides:

- Address storage and traceability

- Warehouse space optimization, inventory analysis

- Compliance with the goods neighborhood, temperature regime and the principles of FEFO, FIFO LIFO, excluding the possibility of goods expiration in warehouse

- Goods packaging, labeling and shipping according to customer requirements

- Automatic control of the product flow

Video about the solution

Reviews

Implementing 1C:WMS allowed us to address many issues referred, first of all, to the influence of "human factor" to work process and create a productive staff system for areas of responsibility, adjusting it online according to the skill level of employees. Besides, we have added new functionality to the warehouse.

LVZ "SARANSKIY" has successfully implemented the 1C:WMS solution. Due to automation, we managed to completely avoid penalties for vehicle downtime, significantly increase turnover and, of course, reduce the number of warehousing mistakes. Order processing became faster, we implemented brand stock counting and reduced workforce size. Also, storage facilities for cargo handling have been improved. Now, the company no longer faces penalties, and all warehouse and business processes fully comply with the requirements to work operations at the federal level.

Currently, 1C:WMS works 24/7. During the operation phase, the system has not required any further changes, thus reflecting the comprehensive approach to the development and implementation of solutions to comply with the project objectives.

The accuracy of product shelf life control has improved. Shipping operation is carried out using the BBD method. On-the-go substitution of tasks became possible. Concerning the destination address, we can provide an employee with a nearby task. Empty hours reduced, the number of tasks performed per day has increased by 15%. Palletizers get the largest number of tasks located one after another during the jorney over the warehouse premises. Now they clear the passages twice faster. The Logistics Director controls the execution of production tasks in a single workplace.

The accuracy of product shelf life control has improved. Shipping operation is carried out using the BBD method. On-the-go substitution of tasks became possible. Concerning the destination address, we can provide an employee with a nearby task. Empty hours reduced, the number of tasks performed per day has increased by 15%. Palletizers get the largest number of tasks located one after another during the jorney over the warehouse premises. Now they clear the passages twice faster. The Logistics Director controls the execution of production tasks in a single workplace.

The complex implementation help us to achieve effective stock management in warehouses of finished products, reduce the time for inventory accounting in the company's accounting system, and reduce labour costs for inputting primary data. The use of radio terminal made it possible to automate the operations of receiving from manufacturing places, inner movements and product picking.

We have successfully developed 12 scenarios of integration with SAP MM, SAP PP and SAP SD modules. In the course of development, matching patterns were designed for operation creating within the SAP system without manual completion. For example, when transmitting information about manufacturing pipes using SAP based on the received data set, we create a production order which reflects the production output, concerning the type, evaluation option, shifts, etc.

We have successfully developed 12 scenarios of integration with SAP MM, SAP PP and SAP SD modules. In the course of development, matching patterns were designed for operation creating within the SAP system without manual completion. For example, when transmitting information about manufacturing pipes using SAP based on the received data set, we create a production order which reflects the production output, concerning the type, evaluation option, shifts, etc.